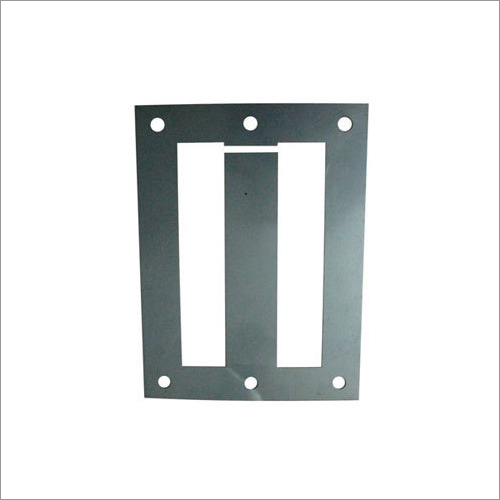

Ei Lamination Cores

Ei Lamination Cores Specification

- Capacity

- Varies as per design

- Low Voltage

- Supports Low Voltage Winding as per transformer spec

- Standard

- IS 3024, IEC 60404

- Rated Voltage

- Applicable for low and medium voltage transformers

- Load Loss

- Low (Designed for optimal efficiency)

- Operating Temperature

- -25C to +105C

- High Voltage

- Supports High Voltage Winding as per transformer spec

- Dimension (L*W*H)

- Customizable as per request

- Cooling Type

- Natural Air / Oil Immersion (as per use)

- Coil Material

- Copper or Aluminium (depends on coil winding)

- Product Type

- Ei Lamination Cores

- Material

- Silicon Steel

- Output

- Magnetic Core for Transformers

- Frequency (MHz)

- 50-60 Hz (typical)

- Efficiency

- High

- Phase

- Single and Three Phase compatible

- Usage

- Transformers and Electromagnetic Applications

- Coil Structure

- EI Core Lamination

- Coil Number

- Custom as per transformer design

- Power Scope

- Up to 1000 kVA (varies by application)

- Weight

- Depends on sizetypically 100g to several kilograms

- Magnetic Flux Density

- 1.5 T max (typical)

- Tolerance

- Tight tolerance for high performance

- Lamination Thickness

- 0.23 mm, 0.27 mm, 0.30 mm, 0.35 mm (typical options)

- Surface Treatment

- Insulation Coating

- Stacking Factor

- Up to 0.96

- Shape

- E & I Profiles

- Core Assembly

- Interleaved & Non-Interleaved

About Ei Lamination Cores

Expert-Grade Silicon Steel Construction

Ei Lamination Cores are manufactured using advanced silicon steel materials, ensuring high efficiency and minimal core loss. The lamination process delivers tight tolerances and supports stacking factors up to 0.96, giving users stability and exceptional performance, even under demanding transformer applications.

Customizable to Your Specific Needs

A wide range of lamination thicknesses and customizable dimensions allow Ei Lamination Cores to be tailored for individual transformer designs. With options for interleaved and non-interleaved cores, users can select exact configurations according to their electrical and mechanical requirements.

Reliable Performance Across Applications

Designed for use in both single and three-phase transformers, these cores perform effectively within a frequency range of 5060 Hz and operate reliably across temperatures from -25C to +105C. With support for high and low voltage windings and various cooling types, they address diverse industrial needs.

FAQs of Ei Lamination Cores:

Q: How are Ei Lamination Cores typically used in transformer applications?

A: Ei Lamination Cores serve as the fundamental magnetic core in both single and three-phase transformers, efficiently managing the magnetic flux and reducing energy losses, thereby improving transformer efficacy in power and electromagnetic applications.Q: What surface treatment is applied to Ei Lamination Cores, and what are its benefits?

A: The cores are treated with a specialized insulation coating, which enhances electrical isolation between laminations, reduces eddy current losses, and ensures long-term durability in demanding operating environments.Q: When should I choose interleaved versus non-interleaved core assembly?

A: Interleaved assembly is recommended for applications requiring lower core losses and improved efficiency, while non-interleaved options may be selected for standard performance or specific mechanical fitting requirements.Q: Where can Ei Lamination Cores be sourced and are they customizable for my project?

A: These cores can be sourced directly from manufacturers, exporters, suppliers, and wholesalers in India, and can be fully customized in dimensions, coil structure, and lamination profile to fit unique transformer specifications.Q: What is the process for ensuring tight tolerances and high stacking factors in these cores?

A: Precision manufacturing processes and stringent quality control, in compliance with IS 3024 and IEC 60404 standards, ensure tight dimensional tolerances and stacking factors up to 0.96, essential for high-efficiency transformer operation.Q: What are the main benefits of using silicon steel for EI core lamination?

A: Silicon steel provides superior magnetic properties, lower energy losses, and high flux density (up to 1.5 T), which translates to improved transformer efficiency and reliability over varied voltage and power scopes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Lamination Core Category

Cvt Transformer Lamination Core

Price 125 INR / Kilograms

Minimum Order Quantity : 200 Kilograms

Material : Highgrade Cold Rolled Grain Oriented Silicon Steel (CRGO).

Product Type : Other, Lamination Core for CVT Transformer

High Voltage : Up to 110 kV

Frequency (MHz) : 50/60 Hz

LTL STAMPING CORE

Minimum Order Quantity : 500 Kilograms

Material : CRGO Electrical Steel

Product Type : Other, Laminated Transformer Core

High Voltage : Up to 33 kV

Frequency (MHz) : 50 Hz

Toroidal Core(Crgo)

Price 105 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Material : CRGO (Cold Rolled Grain Oriented Silicon Steel)

Product Type : Other, Toroidal Core

High Voltage : Up to 33,000 V

Frequency (MHz) : 5060 Hz

3 PHASE CORE STAMPING

Minimum Order Quantity : 500 Kilograms

Material : CRGO (Cold Rolled Grain Oriented) Steel

Product Type : Other, Transformer Core Stamping

High Voltage : Up to 36 kV

Frequency (MHz) : 50 Hz

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS