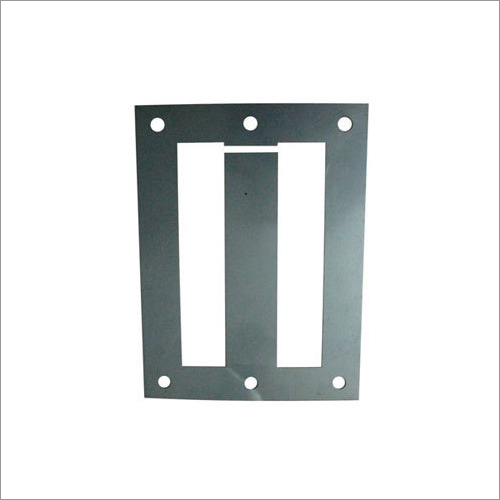

3 PHASE CORE STAMPING

3 PHASE CORE STAMPING Specification

- Dimension (L*W*H)

- Custom sizes; typical 1000 mm x 650 mm x 450 mm

- Coil Material

- High-grade electrical steel

- High Voltage

- Up to 36 kV

- Operating Temperature

- -20C to +60C

- Low Voltage

- 433 V / 690 V / 1100 V

- Cooling Type

- ONAN (Oil Natural Air Natural)

- Capacity

- 100 kVA 2500 kVA

- Standard

- IS 2026 / IEC 60076

- Rated Voltage

- 11 kV / 22 kV / 33 kV

- Load Loss

- As per IS 2026 standards

- Product Type

- Transformer Core Stamping

- Material

- CRGO (Cold Rolled Grain Oriented) Steel

- Output

- For transformer output; compatible with rated transformer capacities

- Frequency (MHz)

- 50 Hz

- Efficiency

- High efficiency (typically above 98%)

- Phase

- Three Phase

- Usage

- Electrical Transformer Core

- Coil Structure

- Laminated Core

- Coil Number

- Three coils

- Power Scope

- Up to 2500 kVA

- Weight

- Varies with size and rating; approx. 250 kg - 400 kg

- Testing

- Subjected to flux density and loss tests

- Packing Type

- Wooden/metal crates as per size

- Surface Finish

- Smooth and rust-proof

- Compatibility

- Suitable for power and distribution transformers

- Stacking Factor

- Above 0.95

- Insulation

- Epoxy coated lamination

- Punching Tolerance

- 0.02 mm

- Edge Quality

- Deburred and smooth edges

- Core Type

- Step-lap design for reduced losses

- Thickness Range

- 0.23 mm 0.35 mm

- Mounting

- Precision slotted for bolt fixtures

- Design Customization

- Available on request

- Moisture Protection

- Yes, with moisture barrier packaging

- Noise Level

- Low noise operation

3 PHASE CORE STAMPING Trade Information

- Minimum Order Quantity

- 500 Kilograms

- Supply Ability

- 50000 Kilograms Per Day

- Delivery Time

- 1 Week

- Sample Available

- Yes

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About 3 PHASE CORE STAMPING

Versatility, Applications, and Unique Features

The 3 PHASE CORE STAMPING is highly versatile, finding applications in commercial substations, industrial complexes, and renewable energy grids. Designed for transformers up to 2500 kVA, its impressive features-such as high insulation, superior stacking, deburred edges, and robust moisture protection-ensure safe, efficient power delivery. Exclusive custom design options make it suitable for specialized requirements in power generation, large-scale manufacturing, and grid distribution settings, maintaining excellence across a range of demanding applications.

Supply Capacity, Sample Policy, and Certification Assurance

We offer substantial supply ability for 3 PHASE CORE STAMPING products, accommodating bulk requirements efficiently with protective wooden or metal crate packaging. Quotations are provided promptly upon inquiry, and sample requests are handled with a clear sample policy to ensure satisfaction before bulk orders. Each stamping adheres to IS 2026 and IEC 60076 standards, ensuring certified quality. Our offerings, combined with export and wholesale capabilities across India, reinforce our commitment to excellence and customer assurance.

FAQ's of 3 PHASE CORE STAMPING:

Q: How does the step-lap design in 3 PHASE CORE STAMPING benefit transformer performance?

A: The step-lap design effectively reduces core losses and enhances magnetic flux distribution, resulting in higher efficiency and improved transformer performance with reduced operational noise.Q: What are the typical applications and installation places for this core stamping?

A: This product is ideal for use in power and distribution transformers, serving roles in commercial, industrial, and renewable energy installations-especially at substations, manufacturing plants, and grid distribution points.Q: What is the process for requesting samples or getting a quotation?

A: You can request samples or a formal quotation by contacting our sales team with your specifications. We respond promptly, outlining our sample policy and detailed pricing based on your requirements.Q: Where is the 3 PHASE CORE STAMPING manufactured, and what certifications does it hold?

A: Manufactured in India at our advanced facilities, the product adheres to IS 2026 and IEC 60076 standards, ensuring compliance with industry benchmarks for safety, quality, and performance.Q: What are the special features that distinguish your 3 PHASE CORE STAMPING?

A: Exclusive features include precision-localized punching tolerance (0.02 mm), high-grade epoxy insulation, smooth rust-proof surfaces, low noise operation, deburred edges, and tailored moisture protection packaging-all contributing to reliability and durability for transformer cores.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Lamination Core Category

Cvt Transformer Lamination Core

Price 125 INR / Kilograms

Minimum Order Quantity : 200 Kilograms

Load Loss : Low (as per IS standard)

Coil Structure : Other, Laminated

Material : Highgrade Cold Rolled Grain Oriented Silicon Steel (CRGO).

Rated Voltage : 11 kV / 33 kV / 66 kV / Customized

Mild Steel Transformer Laminations

Price 129 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Load Loss : Low (Standard as per IS/IEC)

Coil Structure : Other, Laminated Core Structure

Material : Mild Steel

Rated Voltage : Upto 33 kV

Ei Ferrite Core

Price 105 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Load Loss : Low

Coil Structure : Other, Laminated, EI Core

Material : Ferrite

Rated Voltage : Customizable

LTL STAMPING CORE

Minimum Order Quantity : 500 Kilograms

Load Loss : Low Load Loss

Coil Structure : Other, MultiCoil Structure

Material : CRGO Electrical Steel

Rated Voltage : 11 kV / 33 kV

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS