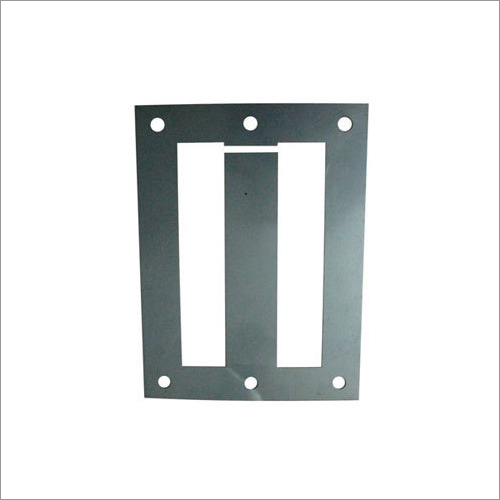

Cvt Transformer Lamination Core

Price 125 INR/ Kilograms

Cvt Transformer Lamination Core Specification

- Coil Material

- Electrolytic Copper

- Operating Temperature

- -10C to +50C

- Rated Voltage

- 11 kV / 33 kV / 66 kV / Customized

- Dimension (L*W*H)

- Customized / As per drawing

- Voltage Booster Type

- Core-Type Lamination

- Load Loss

- Low (as per IS standard)

- Low Voltage

- 400 V / 415 V

- Cooling Type

- ONAN / Oil Natural Air Natural

- Capacity

- Up to 2500 kVA

- Standard

- IS 2026 / IEC 60076 / Customized

- High Voltage

- Up to 110 kV

- Product Type

- Lamination Core for CVT Transformer

- Material

- High-grade Cold Rolled Grain Oriented Silicon Steel (CRGO).

- Output

- Stable AC Voltage Output

- Frequency (MHz)

- 50/60 Hz

- Efficiency

- >98%

- Phase

- Three Phase / Single Phase (as required)

- Usage

- Used in CVT Transformer for voltage regulation and precise measurement.

- Coil Structure

- Laminated

- Coil Number

- Customized as per design

- Power Scope

- Suitable for Medium to High Voltage Applications.

- Weight

- As per dimension and design

- Thickness of Lamination

- 0.23 mm / 0.27 mm / 0.30 mm

- Installation

- Indoor / Outdoor

- Stacking Factor

- >0.95

- Core Loss

- Low Core Loss (1.30 W/kg @ 1.5 T)

- Burr Level

- <0.02 mm

- Noise Level

- Low (<55 dB)

- Mounting

- Horizontal or Vertical mounting possible

- Insulation Level

- Class A / B / F as per requirement

- Packing

- Wooden Pallet / Protective Packing

- Test Certification

- Routine & Type Tested as per standards

- Applications

- Power Transmission, Substations, Metering, Protection

- Core Shape

- Step Lap / C-Type / E&I Type

- Surface Treatment

- Annealed & Anti-rust Coated

Cvt Transformer Lamination Core Trade Information

- Minimum Order Quantity

- 200 Kilograms

- Supply Ability

- 50000 Kilograms Per Day

- Delivery Time

- 1 Days

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Cvt Transformer Lamination Core

Precision Engineering & Superior Materials

Our lamination cores are fabricated from premium cold rolled grain-oriented (CRGO) silicon steel, ensuring stable AC voltage output and high efficiency (>98%). The advanced surface treatment protects against rust, while the thickness and burr control enhance overall core performance and reliability in demanding electrical environments.

Versatile Design & Mounting Options

Available in various core shapes-Step Lap, C-Type, E&I-and insulation classes, these cores accommodate different installation requirements. Capable of both horizontal and vertical mounting, they fit seamlessly into indoor or outdoor setups, meeting customized dimensional and voltage specifications for diverse transformer needs.

Certified Quality & Reliable Performance

Rigorously tested according to IS 2026, IEC 60076, and client specifications, each core is supported by routine and type test certifications. Our packing uses protective materials, ensuring safe delivery and maintaining the low noise and core loss characteristics essential for efficient transformers.

FAQ's of Cvt Transformer Lamination Core:

Q: How is the CVT Transformer Lamination Core installed in various environments?

A: The core is designed for flexible installation and can be mounted either horizontally or vertically, making it suitable for both indoor and outdoor environments. Its protective surface treatments and robust packing facilitate secure installation and long-term operation in diverse settings.Q: What are the benefits of using high-grade CRGO silicon steel in the core?

A: High-grade Cold Rolled Grain Oriented (CRGO) silicon steel enhances magnetic properties, reduces core losses (1.30 W/kg @ 1.5 T), and improves efficiency (>98%). This results in stable voltage output, reliable transformer performance, and long lifecycle in demanding power transmission applications.Q: When should I choose Step Lap, C-Type, or E&I shape for the lamination core?

A: The appropriate core shape depends on your transformer design and electrical requirements. Step Lap shape optimizes magnetic path and minimizes losses, C-Type offers ease of assembly for specific designs, and E&I is suitable for various standard transformer configurations. Consult with our experts for recommendations based on your needs.Q: Where are these lamination cores commonly used?

A: These cores are widely used in power transmission networks, substations, metering systems, and protection circuits, particularly in voltage regulation and precise measurement transformers. Their robust construction meets the rigorous demands of medium to high voltage environments.Q: What process and certifications ensure the quality of the lamination core?

A: Our cores undergo routine and type testing as per IS 2026 and IEC 60076 standards, ensuring compliance with industry specifications. The process includes controlled annealing, anti-rust coating, precision burr control (<0.02 mm), and stacking for superior electrical performance.Q: How does the low noise level (<55 dB) benefit transformer operations?

A: A noise level under 55 dB ensures quiet operation, making it ideal for environments sensitive to sound, such as urban substations or indoor installations. This minimizes disturbance and contributes to a comfortable and efficient working environment.Q: What are the typical voltage and power capacities offered by these cores?

A: Our lamination cores support rated voltages of 11 kV, 33 kV, 66 kV, and can be customized for up to 110 kV. They are suitable for transformer capacities up to 2500 kVA, with low load loss and high efficiency, matching a wide range of application requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Transformer Lamination Core Category

Mild Steel Transformer Laminations

Price 129 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Coil Material : Other , Mild Steel Laminations

Power Scope : Customizable as per requirement

Coil Structure : Other, Laminated Core Structure

Rated Voltage : Upto 33 kV

Ei Ferrite Core

Price 105 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Coil Material : Other , Copper/Aluminum (As per winding)

Power Scope : Low to Medium Power Applications

Coil Structure : Other, Laminated, EI Core

Rated Voltage : Customizable

LTL STAMPING CORE

Minimum Order Quantity : 500 Kilograms

Coil Material : Other , Copper

Power Scope : Up to 1000 kVA

Coil Structure : Other, MultiCoil Structure

Rated Voltage : 11 kV / 33 kV

Assembled Lamination Core Stack

Price 142 INR / Kilograms

Minimum Order Quantity : 500 Kilograms

Coil Material : Other , Copper / Aluminium

Power Scope : Customized as per requirement

Coil Structure : Other, Layered Laminated

Rated Voltage : From 100V up to 50000V (customizable)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS